Why Future-Proofing Matters

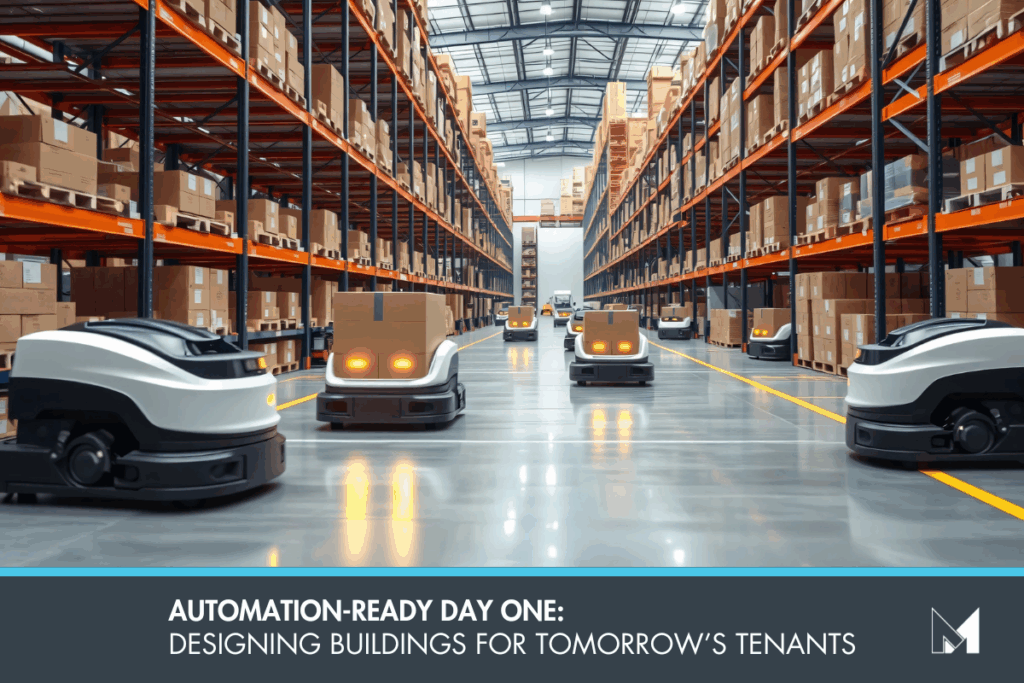

Industrial tenants no longer arrive with just racking and forklifts. Increasingly, they show up with robots, conveyors, and aggressive go-live dates. In this environment, the buildings that lease fastest aren’t the flashiest—they’re the ones designed to let automation plug in seamlessly from day one.

If a warehouse or distribution center requires saw-cut floors, costly change orders, or lengthy retrofits before automation can start, tenants lose precious weeks. Owners and developers who plan ahead gain a competitive edge.

The Market Shift Toward Automation

Automation is no longer a distant trend—it’s rapidly becoming the standard in modern logistics and industrial facilities. Tenants are investing heavily in robotics, AI, and fulfillment technology, and developers who anticipate these needs gain a measurable edge.

- 25% of total capex is expected to go toward automation in the next five years (over ⅓ in logistics and fulfillment) – McKinsey & Company

- Roughly 50% of warehouses will adopt autonomous mobile robots (AMRs) within the next decade, and 10–20% will add automated storage and retrieval systems (AS/RS) – Prologis

- Rework costs still average ~5% of construction budgets, much of it avoidable with early planning – PDH Express

The ROI of “Automation-Ready” Design

Designing for automation upfront pays off in speed, cost savings, and tenant satisfaction. A small shell premium today can translate into faster leasing, fewer headaches, and a stronger long-term investment.

- +0.5–2% shell premium for automation-ready features (extra power capacity, IDF redundancy, slab/joint planning, hanging points).

- Tenant improvement (TI) savings of 4–8+ weeks by avoiding saw-cut/repour, redesign, and network retrofits.

- Reduced rework, sidestepping chunks of that industry-standard 5% waste.

Notes: % and weeks above reflect Method project experience; market and scope vary.

What to Bake Into the Shell

The most successful warehouses anticipate tenant needs before they arrive. By incorporating automation-ready features into the shell, owners can deliver facilities that adapt to robotics, conveyors, and high-tech logistics without costly rework.

🏗️ Floor First

The warehouse floor sets the foundation for automation success, so early planning prevents costly retrofits and downtime.

- Plan joint and embed layouts around VNA aisles and AS/RS corridors.

- VNA aisles require F-min “superflat” floors beyond typical FF/FL standards. – Steel King

🏢 Structure

A flexible and robust structural grid ensures conveyors, catwalks, and sortation systems can be integrated without redesign headaches.

- Use wide, regular bays.

- Pre-detail hanging points and catwalks for conveyors and sorters.

⚡ Power & Data

Future-proofing power and connectivity is critical as automation and AI drive rising energy and network demands.

- Oversize service pads and gear rooms.

- Provide dual-voltage distribution with spares.

- Design for multiple IDFs + fiber ring backbone.

- Install tray “spines” for future cabling.

📶 Networks

Reliable connectivity—Wi-Fi, private 5G, and fiber backbones—keeps robots, scanners, and systems running seamlessly from day one.

- Plan for Wi-Fi mounting and CBRS/private-5G readiness with conduit and rooftop access. – On Go Alliance

🚚 Docks

Well-designed docks improve tenant efficiency, security, and flexibility, especially in high-volume and cold-chain operations.

- Use vertical-storing leveler-ready pits for better seal, security, and cold-chain flexibility. – Rite Hite

🚨 Life Safety

Automation introduces new fire and safety challenges, making smart life safety planning essential for compliance and risk reduction.

- Design ESFR and egress paths with commodity class changes in mind (plastics, totes, batteries). – NFPA

🔋 Battery Charging Zones

Designating safe, code-compliant charging areas helps support tenant fleets of AMRs, forklifts, and other battery-powered systems.

- Plan for ventilation, detection, and layout per OSHA 1910.178(g).

The future of warehousing is automation. Stay ahead of the curve with Method Architecture’s expertise in automation-ready industrial design, helping you create spaces tenants choose first.

Listen to this article: